Applications

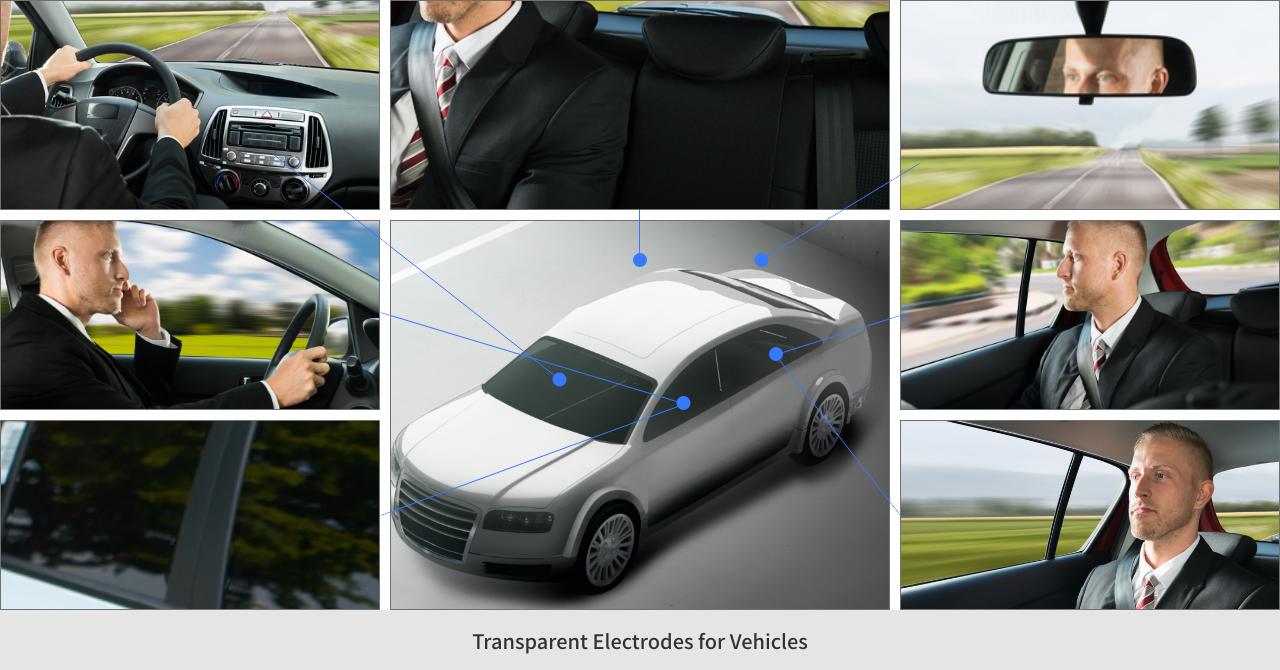

Transparent Heating Panels for Vehicle

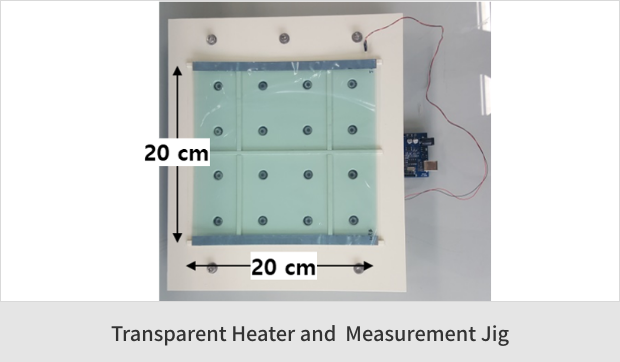

Transparent heater

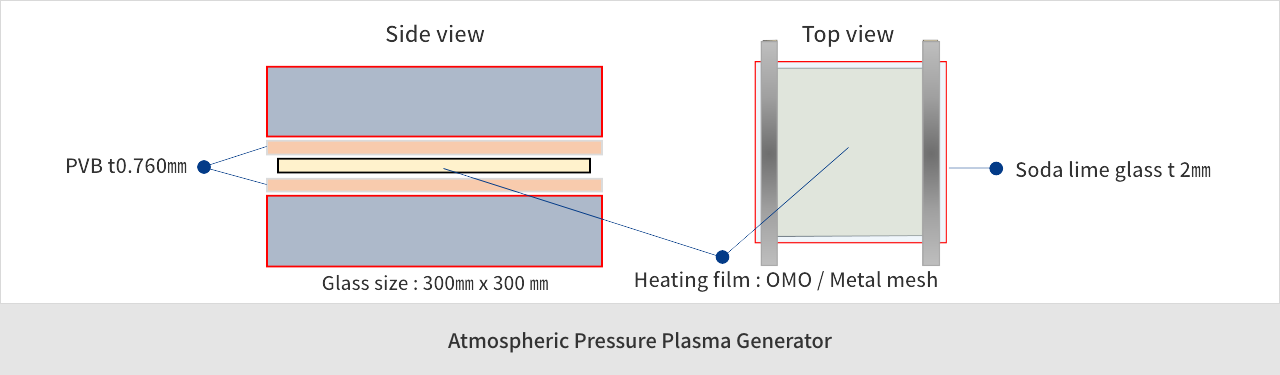

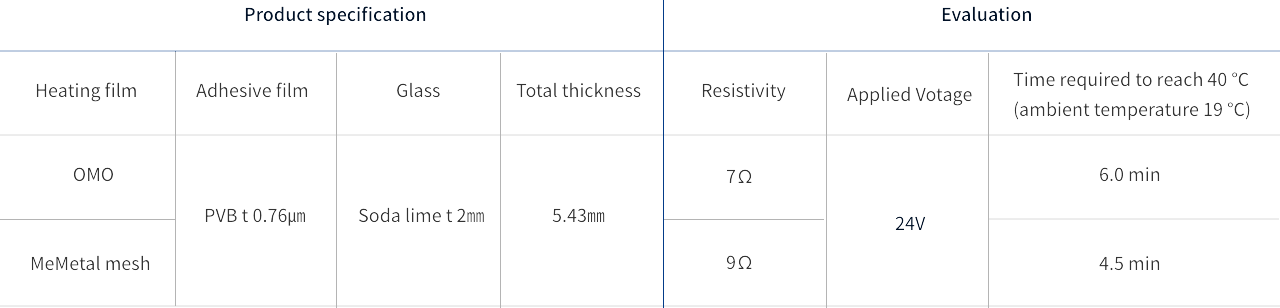

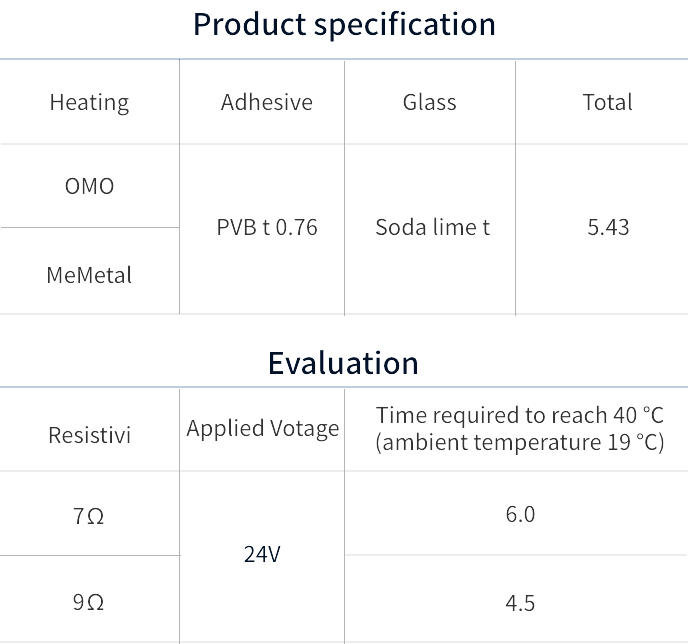

Transparent heaters are advanced glass materials that generate heat when electricity is applied through a conductive material attached to the glass. It is a functional glass with functions such as condensation prevention, defrosting, icing removal, and heating control by automatically adjusting the temperature when the user sets the desired temperature using the controller. MCK Tech developed a transparent heating glass by integrating oxide-metal-oxide nanowires into glass to solve the problems of conventional ITO material-based transparent heaters. Transparent heating glass using conventional ITO material has excellent electrical conductivity and light transmittance, but is expensive and fragile, making it difficult to produce large-area glass. On the other hand, OMO film is highly visible and flexible, making it easy to install on curved glass, and has the advantages of low-power operation and high-speed instantaneous heating with low-resistance components

01 Application

02 Product Details

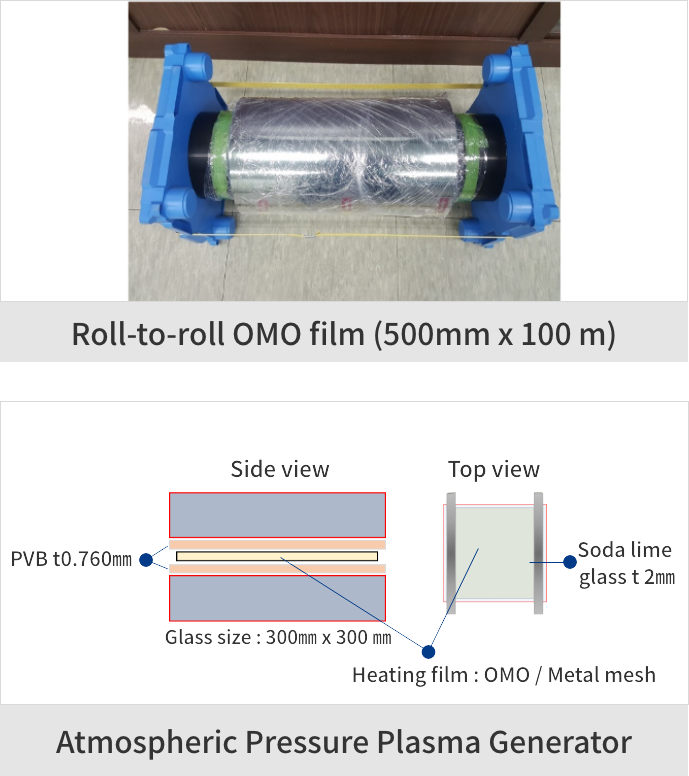

Roll-to-roll process for Metal Mesh

Roll to roll sputter and etching is used to make metal mesh transparent electrode

Sheet resistance and transmittance can be tailored by adjusting mesh width/ pitch

Intentional oxidation layer is made to reduce visibility

Roll-to-roll process for continuity and uniformity

OMO transparent electrodes are manufactured using roll-to-roll sputter

Oxide and metal layers are sequentially sputtered